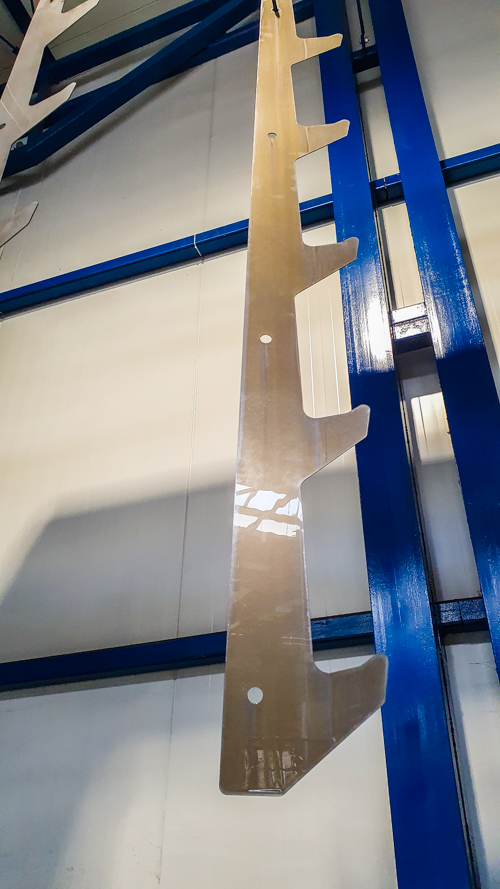

For our client operating on a large automated production line, we implemented our innovative technology for surface washing prior to powder coating, which allowed a significant reduction in gas consumption in the manufacturing process of gymnastic equipment. Thanks to individual gas meters on the burners, it has been possible to accurately determine that previously the daily gas consumption was 210-220 m3 when working about 10 hours a day, whereas now the company only needs 9-10 m3 of gas a day.

WANNA: Capacity 5000l

STATUS BEFORE IMPLEMENTATION:

Washing with phosphate, temp. approx. 45-55 C

Gas consumption approx. 210-220m3 over a 10h working day

STATE AFTER:

Washing with Kairo-SURF chemistry temp. 24 C

Gas consumption approx. 9m3 over a 10h working day

CONCLUSIONS

What needs to be emphasised is that the decrease in gas consumption is not proportional to the decrease in temperature due to the large heat capacity of the water (recall, a 5-cubic metre wash tub), which requires a lot of energy to heat up to a high temperature. In addition, heat loss is driven by the temperature difference between the chemistry and the surroundings. The higher the operating temperature of the chemistry, the greater the heat loss and the faster the bath cools down. We suspect that during the summer season and higher ambient temperatures, daily gas consumption will be even lower. It is certainly also worth noting that working conditions (and perhaps even productivity) in the plant will improve because of the lower temperatures on the shop floor.

Measurements carried out by the plant have proven that the cleaning technology supplied by Kairos brings many benefits to the company, both economically and environmentally. A reduction in gas consumption by more than 20 times compared to previous solutions means significant financial savings for the company. In addition, the reduction in the amount of gas required for production results in lower greenhouse gas emissions, which contributes to environmental protection.