Korozja to nieustanny wróg wszystkich materiałów i powłok, które narażone są na działanie czynników atmosferycznych. Właściwa ochrona przed rdzą i innymi formami korozji jest kluczowa nie tylko dla trwałości, ale również dla bezpieczeństwa i funkcjonalności różnych struktur i urządzeń. Jednym z najskuteczniejszych narzędzi oceny odporności korozyjnej materiałów jest test w komorze solnej, zwany również badaniem w rozpylonej solance.

HomeCategory

Archive: Uncategorized - Kairos Poland

We are making available the presentation Kairos Polska showed at the 18th Wagner Powder and Liquid Coating Symposium. In our presentation, we posited the thesis that 2=10. Reducing the operating temperature of a water bath from 45-50°C to 25-27°C translates into a 10x decrease in energy consumption for heating the bath. In the presentation, we provide evidence for the thesis.

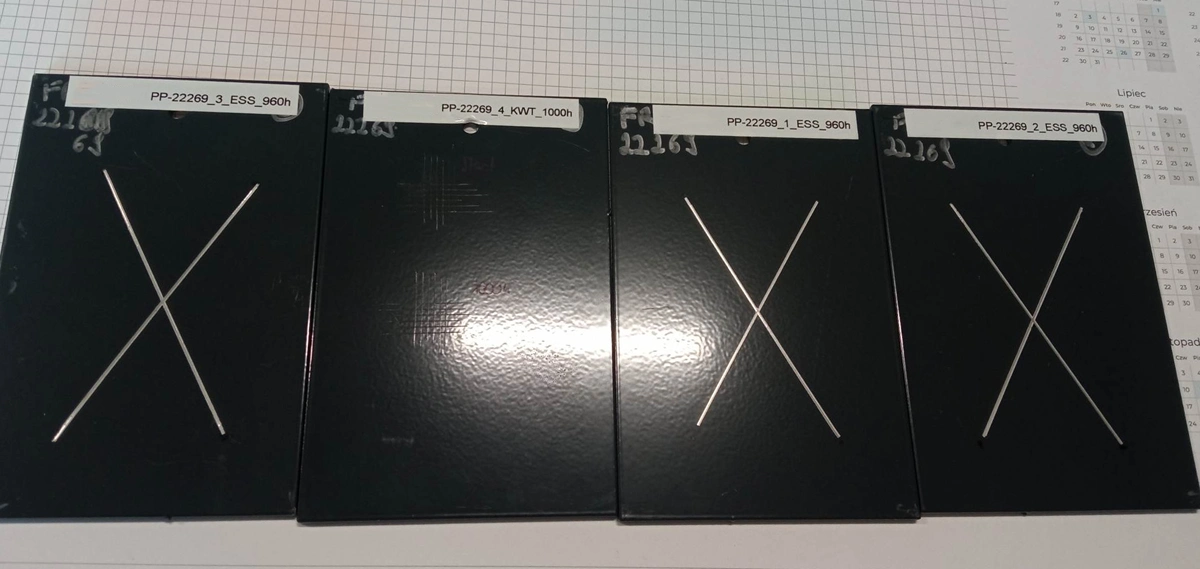

Kontynuujemy serii wpisów poświęconą testom w komorach solnych. Uznaliśmy, że nie ma lepszego sposobu, aby przekonać niezdecydowanych, niż pokazywanie tzw. "twardych dowodów" z testów wykonywanych w komorach solnych, nie tylko na nasze zlecenie, ale również przez naszych potencjalnych klientów.

We are proud of our range of products for surface preparation prior to powder coating and would like to share the extremely satisfying results of our salt chamber tests. In this blog post, we will focus on technical aspects and details that may be of interest to paint line professionals.

If you've been following our company blog you'll remember that not too long ago we wrote about a part-industry and long-term project that we've had the pleasure of looking into for some time now. We are referring to the restoration of a 1934 Packard Twelve Club Sedan 1107 car.

When painting surfaces, many mistakes can be made in both the preparation of the metal surface to be painted and the application of the paint. As a result, the paint film is not perfectly smooth and even, and it degrades or chips quickly. What can be done to avoid mistakes?

Phosphating is a widely used and well-known process and, if all requirements are met, the resulting conversion coating is of good quality. The question arises as to whether it is the optimum process for preparing a surface for powder coating?

A huge amount of electricity is used in industry. It is used to power plant and machinery and, in paint shops, to prepare water baths and dry parts before and after painting. Due to rising energy prices, we are seeing a very strong trend among entrepreneurs to optimise the costs of running powder coating plants. Equally important is the environmental aspect of the search for savings in energy consumption. Kairo-SURF technology can reduce the costs of paint lines by up to 40%.

History knows of many instances where excellent, innovative technologies have languished forgotten in drawers and laboratories. It was the case with the first electric cars, which were developed in the 19th century, and it was the case with Damascus steel, the ability to manufacture which disappeared after the 17th century. One of the more common reasons for this is a lack of willingness to learn about novelty. Meanwhile, a modern approach to the classics generates savings and gives you a competitive edge. It is no different with our most innovative product Kairo-SURF.

At the beginning of the year, we received a call from Mr Artur Kubieniec. He was looking for a solution for a simple surface preparation for varnishing, which he could carry out in his garage and would not need to heat the solution to high temperatures.