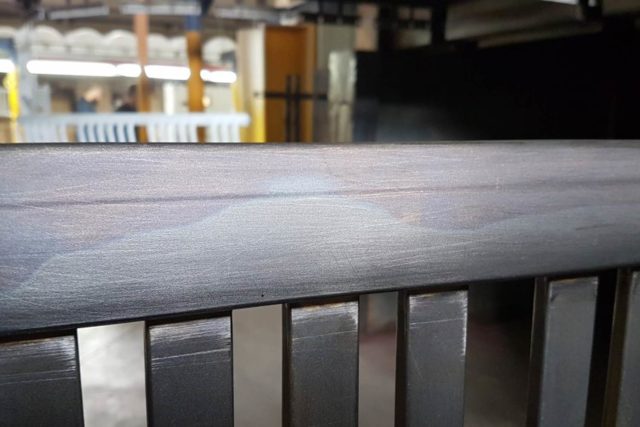

One of the largest manufacturers of bathroom radiators in southern Poland has implemented a Kairos surface preparation chemicals at low temperatures. The company had been using classic products like iron phosphating for years. The products worked at temperatures of over 50 ºC.

The surface preparation line is a typical pass-through line operating in a 3-zone system and a 'branch' with fresh process water.

1. pre-wash (degreasing) with iron phosphating - temperature > 50 ºC

2. basic cleaning (degreasing proper) with iron phosphatising - temperature > 50 ºC

3. Rinsing with process water

4. 'Twig' with fresh process water

It was intended that zone 1 would operate at a higher concentration of iron phosphates preliminarily removing contaminants. The second zone - at a lower concentration - applied an additional layer of phosphates.

Due to the developed surface area of the radiators and the short drip zones, the transfer of the bath meant that the same concentration of iron phosphate was worked in both tanks. This resulted in one long wash zone.

Despite this, the radiators were not washed properly and more than 70 % of some radiator types were repainted.

In addition, the surface preparation products formed huge amounts of phosphate sludge, which deposited in the tanks, on the interior of the washer and blocked the spray manifolds. The iron phosphating products were classified as 'CORRIBLE', posing a chemical burn hazard to the operators. There was also an unpleasant smell of chemicals on the shop floor.

What it is like now that the product has been implemented Kairo-SURF PF?

It was proposed to exclude zone 1 and fill only zone 2 with Kairos chemistry.

- an operating temperature of 25 ºC - this translates into lower gas consumption and a lower hall temperature (improved working conditions)

- working concentration - 0.5 % - previously over 2 %.

- a significant improvement in the quality of washing was achieved - powder paint consumption was reduced due to the single-painting of parts. The number of parts repainted due to undercoating has dropped to virtually zero.

- Increased productivity - overtime has been reduced by more than 15 % for the above reasons.

- Reduction in the number of zones - with fewer media in the line, waste disposal costs can be reduced, while high quality cleaning can be achieved with approximately 750 hours in the salt chamber on steel.

- no sludge - longer bath life - reduced disposal costs, clean system and nozzles

- virtually odourless chemistry

- chemical consumption - 3 times lower than in the case of phosphates

- high drying temperature without degradation of the coating, up to 230 ºC (phosphate is a maximum of 130 ºC).